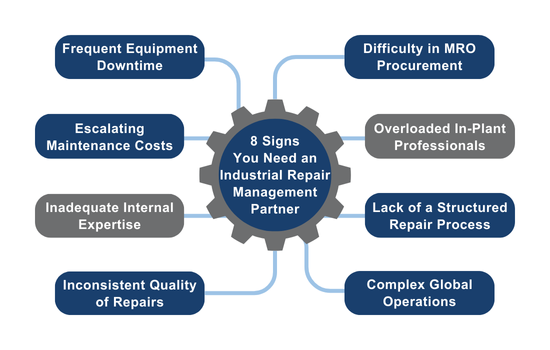

In the fast-paced world of industrial operations, maintaining efficient machinery and minimizing downtime are paramount. As industries grow, the complexity of maintaining and repairing equipment increases exponentially. Many companies struggle to keep up with the demand for timely and effective maintenance, which can significantly impact their productivity and bottom line. If you’re noticing any of the following signs, it might be time to consider partnering with an industrial repair management specialist.

1. Frequent Equipment Downtime

One of the most telling signs that you need an industrial repair management partner is recurring equipment downtime. Persistent malfunctions and breakdowns can halt your operations, leading to costly delays. Partnering with an expert can ensure timely and effective solutions, minimizing your machinery’s downtime and enhancing productivity. Some industrial repair management partners can even help you find the root cause of failures, in turn, helping to prevent future breakdowns.

2. Escalating Maintenance Costs

Are your maintenance costs spiraling out of control? Managing failed components in-house can often lead to inefficiencies and higher expenses. By working with an industrial repair management service, you gain access to a streamlined process that allows you access to the proper repair partners each time a component fails. Leveraging this extensive network of repair partners helps in negotiating better repair rates and ensuring cost-effective solutions for your maintenance needs.

3. Inadequate Internal Expertise

Industrial maintenance mechanics are highly specialized professionals, and finding the right talent in-house can be challenging. If your team lacks the necessary expertise to handle complex repairs, it’s time to bring in a partner. Industrial repair management partners can help connect your team with the right repair supplier, even for rarely failed components.

4. Inconsistent Quality of Repairs

Quality inconsistencies in repairs can lead to recurring problems and further damage to your equipment. A reliable industrial repair management partner ensures that every repair is conducted to the highest standards. Vetted repair suppliers committed to quality provide peace of mind that your machinery is maintained correctly.

5. Difficulty in MRO Procurement

Navigating the complexities of MRO procurement can be a daunting task. Finding reliable industrial parts suppliers, managing inventories, and ensuring timely delivery of parts are critical to maintaining operational efficiency. An industrial repair management partner can simplify this process by managing your MRO procurement needs as well as repairs. By leveraging an extensive network to source high-quality refurbished and new parts, expert industrial repair management partners ensure all your components are available when you need them.

6. Overloaded In-Plant Professionals

In-plant professionals often have extensive workloads, making it challenging to manage repair options for failed parts. This can lead to delays in addressing maintenance issues and scrapping repairable components because purchasing new is easier for plant professionals than finding a repair supplier. Partnering with an industrial repair expert can alleviate this burden by providing specialized repair services, allowing your team to focus on their core responsibilities. This collaboration ensures timely and effective maintenance, enhancing overall productivity and preventing future disruptions.

7. Lack of a Structured Repair Process

If your maintenance strategy lacks a structured repair process, it’s time to rethink your use of resources in-house. Partnering with a repair management expert can help you implement an effective repair plan without the need to develop one from scratch or train your staff extensively. These experts bring established processes for regular repairs, identifying potential issues before they escalate into serious problems. This approach not only extends the lifespan of your equipment but also reduces unexpected downtime, ensuring smooth operations and increased productivity.

8. Complex Global Operations

Managing industrial repair and maintenance across multiple locations and countries adds layers of complexity. A global presence ensures consistent and reliable service wherever you are. Comprehensive industrial repair management solutions are designed to meet the diverse needs of multinational operations, providing seamless support across all your facilities.

Conclusion

If any of these signs resonate with you, it’s time to consider an industrial repair management partner. AH Group offers a comprehensive solution to all your maintenance challenges, backed by a network of reliable repair partners and a commitment to quality and efficiency. By partnering with AH Group, you can streamline your maintenance operations and boost your productivity, establishing your company as a leader in the MRO repair space. Contact AH Group today to learn more about how we can support your business.