What is Component Obsolescence?

Each product has a lifecycle, and component obsolescence occurs when an Original Equipment Manufacturer (OEM) starts to phase out production of a specific component or family of components. Component obsolescence is an on-going difficulty in manufacturing and industrial facilities because not only can upgrading machinery in manufacturing plants be costly, but also the downtime required to upgrade or replace machines can be even more detrimental to manufacturing plants’ budgets and production.

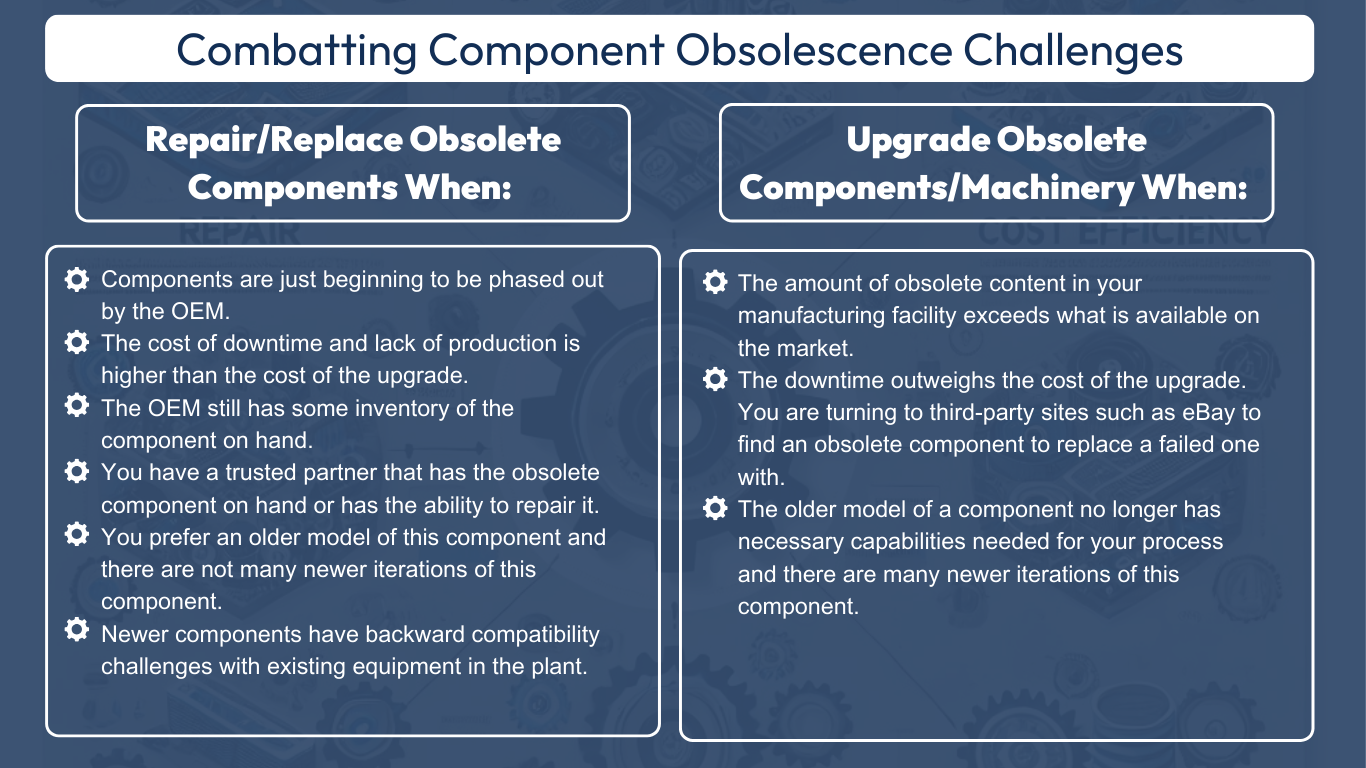

However, when an OEM begins phasing out a component, it does not always require an immediate upgrade to your line’s machinery. With third-party sellers and repair partners, obsolete components can often be sourced or repaired to continue production in your plants. To mitigate challenges caused by component obsolescence, it is important to know when to repair or replace failed obsolete components using third parties and when it is time to upgrade components or machinery. If you are facing challenges due to component obsolescence, use the checklist below to help you decide what is best for your plant.

Combating Challenges Caused by Component Obsolescence

To combat challenges caused by component obsolescence, it is important to know when to repair or replace failed obsolete components and when to upgrade obsolete components and machinery. By starting upgrades on less complicated, mature components first, you can begin the upgrading process without having to replace all machinery at once. Often, it is best to save upgrading intelligent products, such as PLCs, Human Machine Interfaces (HMIs), servo systems and CNC hardware/software, for last to avoid the high cost for as long as possible.

In the meantime, before you upgrade, contact AH Group at info@ahgroupna.com to talk to us about our services for obsolete components. We’d be happy to help understand your facility’s situation further to uncover opportunities for repairing obsolete components instead of upgrading right away.