In various manufacturing operations involving precision machining, spindles are a critical part of the manufacturing process. Spindles allow manufacturers to cut and finish raw materials—one of the primary steps in the manufacturing process. Learn more about this crucial component and how to properly care for your spindles below.

What is a spindle?

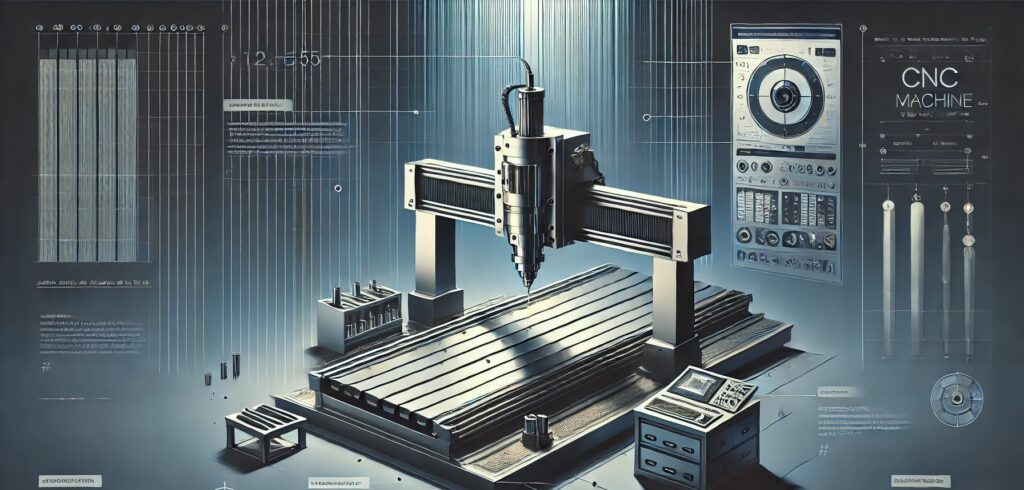

A spindle is a metal component that is often the largest machine tool inside of a CNC machine. CNC machines are used in the manufacturing process to cut raw materials into the required shapes. Spindles are the part inside of the machine that performs the cutting process. Spindles have various tools that a machinist can attach to them, allowing them to cut wood, metal, and many other raw materials.

What is a spindle used for?

CNC machines are used in a variety of industries, which means spindles are also used in many different facilities. Spindles can cut materials for manufacturing facilities in automotive, aerospace, defense, electronics, furniture, medical, and more. Since many industries raw materials cut down into complex shapes for their manufacturing processes, CNC machines can be programmed to work for many different purposes.

How do spindles typically fail?

The most common reason a spindle fails is due to failure of the bearings within the spindle. Bearings within spindles can typically last for many years based on their application, but they can fail quicker if they are not properly taken care of. Often, bearings will fail quicker if the spindle is not used for its intended application or if raw material chips from the cutting process enter the spindle and ultimately reach the bearings.

How can you fix a spindle?

The process for repairing a spindle depends on the severity of damage. Often, the bearings (and other components) within are replaced. Other times, the motor or sensors need to be reset to allow the spindle to work to its fullest potential again. Regardless, seeking professional help from spindle experts is the best way to ensure you are getting a quality repair for your spindle.

How can you prevent a spindle from failing?

Taking preventative measures is a great way to ensure a long life for your spindle. A few ways to properly care for your spindle are:

Lubrication

If your spindle is an Oil-Applicated spindle, ensure there is proper oil flow to the bearings.

If your spindle is a Greased-For-Life spindle, ensure you periodically checking the temperature.

Coolant system maintenance

Maintaining the coolant system helps prevent overheating.

Avoiding overloading

Make sure you are using appropriate speeds, feeds, and depths to prevent overloading the spindle.

Temperature checking

During use, ensure your spindle is operating at normal temperatures.

Periodically check the temperature of the spindle or pause the cutting process to ensure the spindle does not overheat.

Cleaning

After the cutting process, ensure you are cleaning the spindle and tools from all debris.

Conclusion

CNC machines are an integral part of the manufacturing process, and maintaining your CNC machine’s efficiency starts with ensuring your spindles are working properly. At AH Group, we work with the industry’s leading experts on spindles to guarantee each spindle repair is the highest quality. Learn how to unlock the untapped potential of your spindles by contacting info@ahgroupna.com